Maximize Your Next Retrofit Using the Right Tools With The Right Refrigerants to

As the refrigerant recovery and reclamation, industry continues to meet the environmental regulatory requirements that will eventually phase out Hydrochlorofluorocarbons (HCFCs), and ozone-depleting Hydrofluorocarbons (HFCs), a wide range of new non-ozone depleting HFCs have become available as alternatives.

In order to implement the alternative HFCs, HVAC technicians will play a leading role by transitioning systems through retrofitting.

Before beginning a retrofit, it is important to remember that every system is unique. Be aware of a system’s operational characteristics.

To start, make sure you have the basic tools on hand, such as a recovery unit, vacuum pump, micron gauge, charging scale manifold and a temperature meter. Note the material compatibility and the condition of the existing seals and gaskets. Seals and gaskets in the “O” Ring configuration, along with other elastomers used in the system, must be changed when going from an HCFC to a HFC.

To start, make sure you have the basic tools on hand, such as a recovery unit, vacuum pump, micron gauge, charging scale manifold and a temperature meter. Note the material compatibility and the condition of the existing seals and gaskets. Seals and gaskets in the “O” Ring configuration, along with other elastomers used in the system, must be changed when going from an HCFC to a HFC.

Also check the following:

• Use an updated unit that’s compatible with the new refrigerant.

• Use the correct PT data for the refrigerant you are working with.

• Use “Green Chill” Best Practices to ensure that your refrigeration equipment is leak-free when installed.

• Check component’s compatibility with selected refrigerant.

To verify accuracy, make sure that the instruments used in the processes are accurate and calibrated. Gauges that are even off by 2-3 PSIG could result in significant operational deficiencies. Many of the measurements taken during the retrofit are so small that it cannot be made with a mechanical gauge, or determined by evacuation time or the sound of the pump. A tool such as the YELLOW JACKET SuperEvac™ LCD vacuum gauge can help measure vacuum suction levels.

During the retrofit, it’s crucial to ensure proper superheat, subcooling and operating control set points.

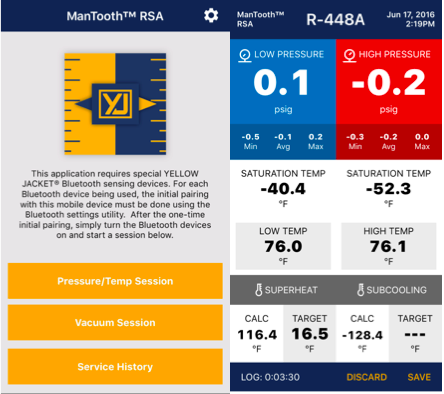

To get a reliable and precise readout, use a digital gauge such as the YELLOW JACKET ManTooth Wireless Digital P/T Gauge or YELLOW JACKET Digital Refrigeration System Analyzer.

To get a reliable and precise readout, use a digital gauge such as the YELLOW JACKET ManTooth Wireless Digital P/T Gauge or YELLOW JACKET Digital Refrigeration System Analyzer.

With the YELLOW JACKET ManTooth Digital Pressure/Temperature Gauge, service technicians can get accurate (+/- .1%), hands-free digital readings though Bluetooth technology. It comes with a free app (for both iOS and Android devices), so technicians can access over 110 refrigerants. The ManTooth also provides data logging and screenshot capabilities so technicians can more easily keep track and access data.

Alternatively, the YELLOW JACKET Digital Refrigeration System Analyzer displays readings in analog, digital or a combination of both. It also monitors two pressures, two live temperatures, subcooling and superheat, and saturation temperatures (liquid and vapor) for nearly 100 refrigerants. There is a built-in pressure/temperature chart reference screen for all refrigerants as well as a built-in, full-scale vacuum sensor that reads deep vacuum levels down to 10 microns. And with dual “K-Type” temperature-compensated sensor ports, the unit can take simultaneous suction and liquid readings.

The YELLOW JACKET Digital Refrigeration System Analyzer allows for fast and sensitive leak detection. It provides real-time pressure data in selectable time increments: 0.1, 0.2, 0.5, 1 and 2 seconds. It also displays and records max/min pressures, logs data for onscreen review (or USB export to PC), and tracks / exports date and time for useful data logging. Additionally, you can manually enter elevation so that you can be sure that the pressure compensation is accurate.

With technology such as the YELLOW JACKET ManTooth and the Digital Refrigeration System Analyzer in hand, technicians have access to accurate and fast readings, as well to excellent instruments and software tools to assist in transitioning the HVACR industry to meet changing environmental regulations.